Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Choosing the right materials for your projects is crucial. The PVC film sheet is an excellent choice, offering versatility and durability. Many professionals and DIY enthusiasts appreciate its unique properties.

A high-quality PVC film sheet can enhance aesthetic appeal and functionality. It comes in various thicknesses and finishes, making it adaptable. Whether it’s for packaging, signage, or crafting, options abound. However, finding the right type can be challenging. The market is filled with choices, and not all may meet your needs.

Consider what you truly require. Reflect on aspects like texture and transparency. Some may prioritize cost, while others value sustainability. Selecting a PVC film sheet often calls for careful thought. Despite the overwhelming options, thoughtful decision-making can lead to successful outcomes.

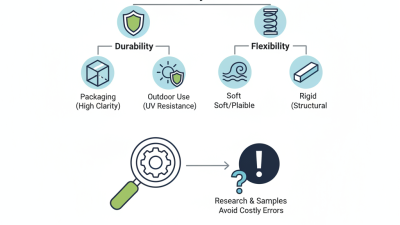

When selecting PVC film sheets, several factors deserve careful consideration. The thickness of the sheet is crucial. Thicker sheets offer better durability. However, they can be heavier and harder to manipulate. Consider the weight of the project. You may want a thinner sheet for easier handling.

Next, think about the finish. PVC film sheets come in various textures and finishes. A matte finish reduces glare but may show fingerprints. Glossy surfaces are shiny and easy to clean. Try to visualize how the finish will suit your needs. Color options also play a vital role in your selection. Bright colors can energize a design, while neutral tones offer elegance.

Another point to ponder is usage. Will the sheets be used indoors or outdoors? UV resistance is vital for outdoor applications. Indoor sheets may focus more on aesthetic qualities. Reflect on where your project will be displayed. It's easy to overlook some of these elements, so take your time. A careful review could enhance your final result significantly.

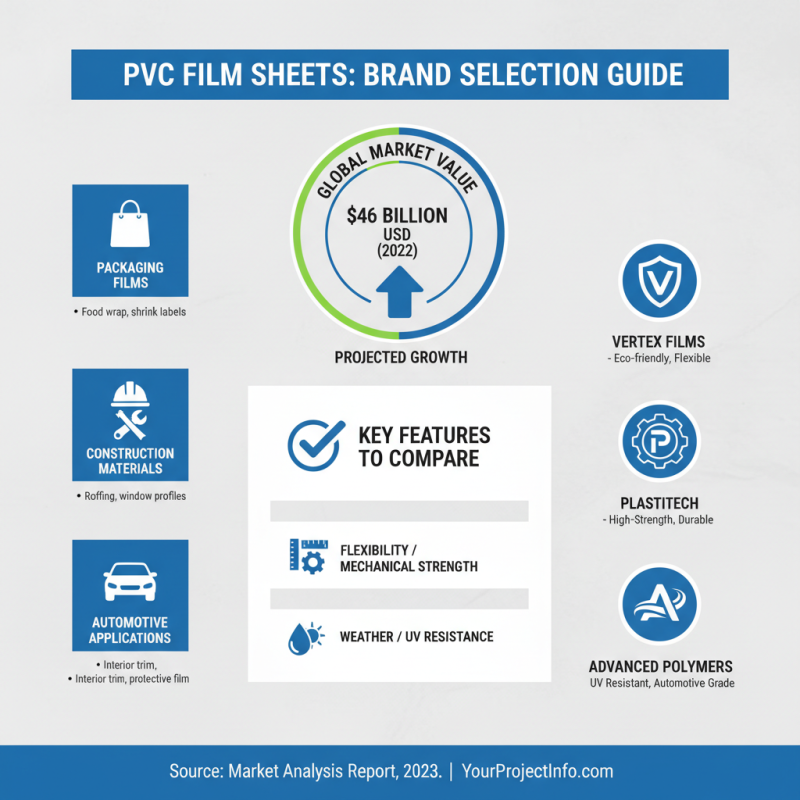

When selecting PVC film sheets for your projects, understanding the features of various brands is crucial. Market analysis indicates that the global PVC film market was valued at approximately $46 billion in 2022 and is projected to grow significantly in the coming years. The diversity in product offerings can cater to needs across packaging, construction, and automotive industries.

Many brands highlight unique qualities. Some focus on UV resistance, enhancing longevity in outdoor applications. Others prioritize flexibility for intricate designs or durability for heavy-duty usage. However, not every brand offers the same level of transparency or color stability. Reports show that a significant percentage of users have faced issues with color fading over time.

Moreover, while many manufacturers claim sustainability in their production processes, not all uphold these practices genuinely. The recycling rates for PVC remain low, raising questions about environmental impact. It’s essential to carefully assess the commitment of brands towards eco-friendly alternatives, ensuring that choices made do not compromise sustainable principles. Understanding these nuances is vital for making informed decisions.

PVC film sheets find extensive applications across various industries, showcasing their versatility. In the packaging sector, these sheets accounted for approximately 40% of the total PVC demand in 2022, according to industry reports. Their durability and water resistance make them ideal for packaging food products. Moreover, they can withstand varying temperature conditions, which is essential for modern supply chains.

In the automotive industry, PVC film sheets are used for interior and exterior applications. They provide a protective layer that increases the longevity of car parts. A study highlighted that over 25% of car manufacturers are now integrating PVC materials to reduce weight and enhance fuel efficiency. This trend is indicative of the industry's focus on sustainability.

However, challenges remain. The recycling of PVC film sheets is less straightforward compared to other materials. Many facilities are still unprepared for effective recycling processes. This leads to increased waste generation. Addressing these issues is vital for the future of PVC applications. Industries must focus on improving recycling techniques to minimize environmental impact.

When selecting PVC film sheets, thickness and durability are crucial factors. Thicker sheets often provide better strength and longevity. A thickness of 0.5mm works well for general purposes. However, a thickness of 1mm is ideal for heavy-duty applications. The choice will depend on your specific project needs and conditions.

Durability is influenced by the material's resistance to wear and tear. Some PVC sheets can withstand high temperatures, while others may not. Testing the sheets in real-life scenarios can highlight unexpected weaknesses. Having a backup plan or alternative materials can enhance your project’s success.

**Tip:** Always consider environmental factors that can affect performance. For indoor uses, lighter sheets may suffice. For outdoor applications, prioritize UV resistance. This can save you from future headaches. Keep a record of the materials used for easier assessments later.

| Thickness (mm) | Durability (Years) | Weather Resistance | Tensile Strength (MPa) | Price ($ per sqm) |

|---|---|---|---|---|

| 0.15 | 5 | Fair | 20 | 2.50 |

| 0.25 | 7 | Good | 25 | 3.20 |

| 0.30 | 10 | Excellent | 30 | 4.50 |

| 0.50 | 15 | Superior | 35 | 6.00 |

| 0.75 | 20 | Outstanding | 40 | 8.00 |

PVC film sheets are versatile materials for various DIY projects. They can be used for crafting, home improvement, and even art. Their durability and affordability make them an excellent choice. Use them to create custom drawer liners, protective surfaces, or even decorative wall panels.

When working with PVC film sheets, consider the thickness you need. Thicker sheets offer more protection but can be harder to cut. Cut them with sharp scissors or a utility knife for clean edges. To avoid mistakes, measure twice before cutting. Small errors can lead to waste.

Additionally, think creatively about how to use colors and textures. Clear sheets can add a sleek look to projects, while colored sheets can brighten up a room. Experiment with layering sheets to create unique effects. Sometimes, what seems like an error can turn into an innovative design.

Tip: If you need to adhere sheets to surfaces, use double-sided tape for easy adjustments. It allows for repositioning if necessary. Always test on a small area first to ensure compatibility. This can save you from larger issues down the road.

This chart showcases the innovative uses of PVC film sheets across various DIY projects, highlighting the demand for different thicknesses and finishes.