Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Choosing the right PVC compound for your project is crucial. It determines durability, flexibility, and overall performance. Industry expert, Dr. Emily Chan, emphasizes, “The right PVC compound can make or break your application.” Selecting the appropriate compound requires careful consideration of several factors.

Different projects require different characteristics in PVC compounds. Understanding your specific project's needs is essential. Temperature resistance, color, and chemical exposure all play significant roles. Sometimes, the perfect compound may not be available, forcing adjustments in your design. Additionally, knowing the supplier's reputation can help avoid low-quality materials.

Mistakes in choosing PVC compounds can lead to costly consequences. Improper selection may result in weak structures or unwanted chemical reactions. Take the time to assess your options thoroughly. The process can be complicated, yet worth the effort for successful outcomes. Reliable testing and consultation can guide you through this complex decision.

PVC compounds come in various types, each with unique properties. Understanding these differences is crucial for project success. Rigid PVC is commonly used for applications like pipes and fittings. Flexible PVC, on the other hand, finds its place in wiring and plumbing. The American Chemistry Council states that about 13 million tons of PVC were produced in the U.S. in 2022, showcasing its importance in various industries.

Different additives can significantly alter the performance of PVC compounds. For instance, impact modifiers enhance toughness. This is vital for outdoor applications, where weather resistance is critical. According to industry reports, using high-quality impact modifiers can improve durability by as much as 30%. However, choosing the wrong modifier may lead to brittleness, causing failure in applications. It’s a tricky decision that demands careful consideration.

Thermal stability is another key factor. Some compounds resist degradation better under heat, while others may soften too quickly. This outcome can affect the lifespan of the final product. The global demand for PVC compounds continues to rise, yet not all formulations meet specific performance criteria. Manufacturers must continually evaluate their choices to avoid costly mistakes in production.

When working on a project that involves PVC, it’s crucial to assess your specific requirements accurately. Consider the intended application of the PVC compound. Will it be exposed to harsh environments, or is it for indoor use? High-impact and weather-resistant formulations might be necessary for outdoor projects, while softer compounds can suffice for indoor applications. Evaluate the mechanical properties required; flexibility may be essential for some designs, while rigidity may be preferred in others.

Next, think about the processing conditions. Some PVC compounds require specialized equipment or heat settings, which can affect production speed and costs. Identify whether you need a compound that can be easily molded or extruded. It’s also important to factor in the desired aesthetic features, such as color or transparency. Be aware that the more features you require, the more complex your choice becomes.

Lastly, remember the sustainability aspect. Some PVC compounds are more environmentally friendly than others. While choosing a more sustainable option might seem appealing, it’s vital to verify if it meets your performance needs. This balancing act can often provoke reflection on your priorities. Consider all these elements carefully; the wrong choice can lead to project delays or failures.

| Project Requirement | Recommended PVC Compound | Properties | Applications |

|---|---|---|---|

| High Impact Resistance | Impact Modified PVC | Excellent toughness and durability | Automotive parts, safety equipment |

| High Temperature Resistance | Heat Stabilized PVC | Stable at high temperatures | Electrical insulation, pipes |

| Chemical Resistance | Chemical Resistant PVC | Resistant to acids and solvents | Chemical handling, laboratory equipment |

| UV Stability | UV Stabilized PVC | Protects against UV degradation | Outdoor applications, constructions |

| Flexibility | Flexible PVC | Good flexibility and elongation | Hoses, cables, weather strips |

Choosing the right PVC compound starts with understanding performance characteristics. The properties of PVC compounds can significantly affect project outcomes. For example, flexibility and tensile strength are two critical factors. According to the Plastics Industry Association, compounds with higher tensile strength endure larger stress before breaking, making them ideal for construction applications.

Another key characteristic is thermal stability. Some PVC compounds can withstand higher temperatures, which is vital in various industrial applications. A report from the Vinyl Institute indicates that compounds with enhanced thermal stability can maintain their integrity even in extreme conditions. This property is crucial for outdoor installations exposed to sunlight and heat.

However, performance characteristics are not one-size-fits-all. The right choice involves trade-offs. A compound with high flexibility may sacrifice strength. It's essential to evaluate the specific requirements of your project. Consider the environmental factors and stress levels your application will face. This reflective approach helps ensure you do not end up with a material that underperforms in critical areas.

When selecting a PVC compound, cost and availability play crucial roles. Different formulations can vary significantly in price depending on their composition and quality. For instance, flexibility can increase costs, while basic grades are often more affordable. It’s essential to assess your budget carefully. A cheaper compound might save money initially, but it could lead to higher replacement costs down the line.

Availability is another factor to consider. Some specialized PVC compounds may not be readily available in your region. This can delay your project and increase overall expenses. Local suppliers might have limited options, which can create frustrating hurdles. It’s important to verify sourcing and lead times before making a final decision. Balancing price and accessibility is not always straightforward and requires thorough research.

Your project’s specific needs will ultimately guide your choice. However, relying solely on cost can be risky. Quality must not be compromised for savings. Sometimes, the best choice is a medium-priced compound that offers just the right balance. Be sure to reevaluate your options carefully to avoid potential pitfalls. A hasty decision today may lead to regrets tomorrow.

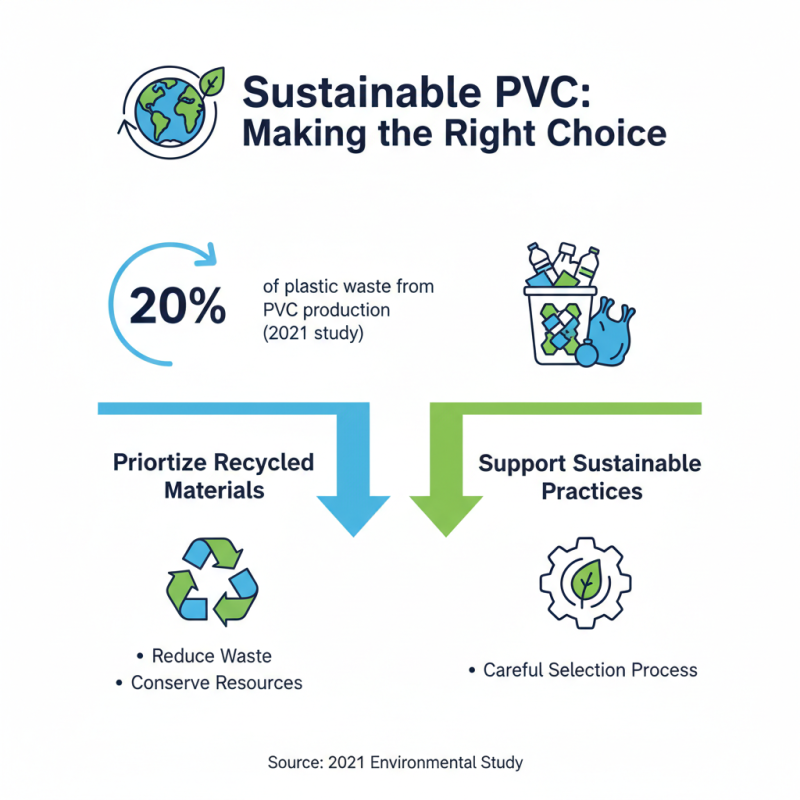

When choosing a PVC compound, environmental impact is crucial. A 2021 study indicates that PVC production contributes to 20% of plastic waste. This fact necessitates a careful selection process. The right compound should support sustainable practices. Look for options that utilize recycled materials. This can help reduce waste and conserve resources.

Tip: Always check for eco-friendly certifications. Many compounds now meet stringent environmental standards. Brands that prioritize sustainability often disclose this information. It’s vital to verify claims for authenticity.

Another factor to consider is lifecycle analysis. Understanding how a PVC compound behaves at the end of its life can influence your choice. Reports suggest that many PVC products can be recycled multiple times, which can significantly reduce their overall environmental footprint. However, not all compounds are created equal. Some may release harmful chemicals during breakdown.

Tip: Consider the end-use of your PVC. Will it be in a product requiring durability? Or can it be in a temporary setting? Adjusting your choice based on usage can make a difference. Being mindful of these factors helps in making informed decisions.