Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

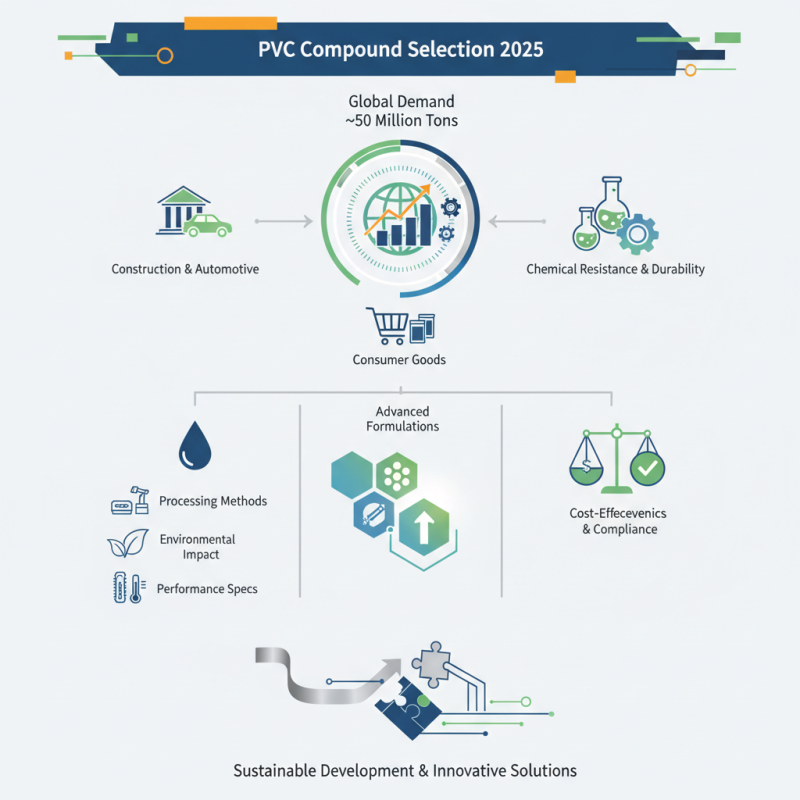

In 2025, the selection of the appropriate PVC compound for construction and manufacturing projects has become increasingly pivotal for industry professionals. According to a report by the PVC Coalition, the global demand for PVC is projected to reach approximately 50 million tons by 2025, highlighting the material’s critical role across various applications, including construction, automotive, and consumer goods. The properties of PVC compounds, such as durability, chemical resistance, and cost-effectiveness, contribute to their widespread acceptance and utilization in diverse sectors.

As the market continues to evolve, understanding the distinct characteristics of different PVC compounds is essential for optimizing performance while ensuring compliance with regulatory standards. A recent analysis by Smithers Pira suggests that advancements in PVC formulation technologies will enhance material properties, thus making the selection process more complex yet rewarding. Professionals must consider factors such as processing methods, environmental impact, and performance specifications to effectively choose the right PVC compound for their specific project needs. This informed decision-making will be crucial in harnessing the full potential of PVC compounds, contributing to sustainable development and innovative solutions in 2025 and beyond.

When selecting the right PVC compound for your project, it is essential to understand the various types of PVC compounds and their applications. PVC, or polyvinyl chloride, is a versatile thermoplastic widely used in construction, electrical, automotive, and medical industries. According to a report by the American Chemistry Council, the demand for PVC is expected to grow at a CAGR of 4% through 2025, with increasing applications in sustainable building materials and high-performance pipes.

Different applications require specific formulations of PVC compounds. For instance, for construction applications, the use of rigid PVC is prevalent due to its strength and durability. In contrast, flexible PVC is often used in plumbing and electrical wiring due to its excellent elasticity and resistance to environmental stress. A recent study published in the Journal of Plastic Science highlighted that over 60% of PVC consumption comes from the construction industry, noting the necessity for tailored compounds that meet stringent regulatory standards for safety and performance.

Understanding the properties of various PVC compounds also helps in optimizing your project's performance. For example, incorporating additives like stabilizers and plasticizers can enhance flexibility and UV resistance, making these compounds suitable for outdoor applications. According to a market analysis by ResearchAndMarkets, the global PVC additives market is projected to reach $5 billion by 2026, indicating a growing trend toward advanced material solutions that cater to specific industry needs. As you prepare for your project in 2025, leveraging this knowledge about PVC compound characteristics will allow for informed decisions that align with both performance requirements and industry standards.

Choosing the right PVC compound for your project in 2025 requires a careful assessment of several key factors that can significantly impact the performance, durability, and cost-effectiveness of your final product. Firstly, understanding the application environment is crucial. PVC compounds exhibit different properties depending on their formulation, such as flexibility, chemical resistance, and temperature tolerance. According to industry reports, the global PVC market is projected to reach a value of $60 billion by 2025, underscoring the importance of suitable material selection to meet growing demands.

In addition to application requirements, processing characteristics play a vital role in selecting the right PVC compound. Factors like melt flow index and compatibility with processing equipment can influence production efficiency and the quality of the final product. A recent study indicated that manufacturers experienced a 15% increase in production efficiency by optimizing the PVC compounds used in their operations. This can lead to considerable cost savings, making it essential to collaborate with suppliers who provide detailed material data sheets.

Tips: Always request samples of the PVC compounds you're considering to test their performance in your specific applications. Additionally, consult with technical experts to ensure that you choose a compound that not only meets mechanical and thermal specifications but also complies with environmental regulations that may be enforced in 2025.

| Key Factor | Description | Importance Level | Examples of Applications |

|---|---|---|---|

| Mechanical Properties | Assessing strength, flexibility, and durability of the compound. | High | Pipes, Fittings, and Window Frames |

| Thermal Stability | Resistance to heat and temperature fluctuations without deforming or degrading. | Medium | Electrical Insulators, Outdoor Applications |

| Chemical Resistance | Ability to withstand exposure to chemicals without degradation. | High | Chemical Handling Systems, Medical Applications |

| UV Resistance | Ability to withstand degradation from UV exposure. | Medium | Garden Furniture, Outdoor Decorations |

| Processing Characteristics | Ease of manufacturing and compatibility with processing technologies. | High | Extrusion, Injection Molding Applications |

When choosing the right PVC compound for your project, understanding the various types of compounds available is crucial to meet specific requirements. PVC compounds are typically categorized into rigid, flexible, and foamed materials, each serving different applications and offering distinct benefits. According to the "Global PVC Compounds Market Report 2023," flexible PVC compounds, which make up approximately 40% of the total PVC compound market, are popular in applications such as plumbing, electrical insulation, and automotive parts due to their excellent elasticity and impact resistance.

Rigid PVC compounds, on the other hand, represent about 35% of the market and are widely used in applications requiring durability and strength, such as pipes, windows, and door profiles. The rigid variant is noted for its low cost, ease of processing, and UV resistance, making it ideal for outdoor applications. Meanwhile, foamed PVC is gaining traction, accounting for around 15% of the market, due to its lightweight and excellent thermal insulation properties, making it suitable for construction and signage uses. Evaluating the mechanical properties and thermal stability of these compounds, as highlighted in the "Plastics Industry Analysis 2024," is vital in determining their suitability for specific projects.

Overall, the decision to choose the right PVC compound should factor in these variations, along with considerations of environmental impact and lifecycle, especially given the growing emphasis on sustainable materials and practices in the industry. Selecting a compound that aligns with both functional and environmental goals will ensure project efficacy and longevity.

When selecting the right PVC compound for your project, thorough testing and evaluation are crucial to ensure performance and compliance. Start by defining the specific requirements of your application, considering factors like temperature resistance, mechanical strength, chemical exposure, and flexibility. Establish a series of tests that correspond to these requirements, such as tensile strength tests, impact resistance measurements, and thermal stability assessments.

Once you have identified the critical parameters, conduct comparative analyses between different PVC compounds. Utilize standardized testing methods to ascertain the material properties under controlled conditions. It’s essential to evaluate the long-term performance of the PVC compound, including aging tests that simulate real-world exposure to environmental conditions. Document your findings meticulously to facilitate informed decision-making. By implementing these best practices, you can select a PVC compound that not only meets your project specifications but also enhances the overall durability and reliability of your final product.

This chart displays the performance evaluation of different PVC compounds based on key parameters such as tensile strength, thermal stability, and chemical resistance. These metrics are crucial for selecting the appropriate PVC compound for construction projects.

In 2025, the landscape of PVC compounds is poised for significant transformation, driven by evolving market demands and technological advancements. One of the most notable trends is the increasing focus on sustainability. As environmental awareness continues to rise, manufacturers are prioritizing the development of eco-friendly PVC compounds that minimize environmental impact. These innovations may include the use of recycled materials or bio-based additives, which not only enhance the performance of PVC but also align with global sustainability goals. This shift towards greener alternatives will influence project specifications, as stakeholders seek materials that comply with regulatory standards and cater to consumer preferences for sustainable products.

Moreover, advancements in formulation technologies are leading to the creation of specialized PVC compounds tailored for diverse applications. Enhanced thermal stability, chemical resistance, and improved mechanical properties are becoming standard expectations, allowing engineers and designers greater flexibility in their projects. The incorporation of smart additives that can respond to environmental stimuli is also gaining traction, enabling the development of multifunctional materials that enhance product performance. As these technological innovations continue to emerge, project managers will need to stay informed on the latest developments to ensure they select the most suitable PVC compounds that meet both performance criteria and future market trends.