Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

PVC Film Sheet plays a vital role in various industries. It is known for its versatility and durability. Experts emphasize its importance in manufacturing. Dr. Emily Hart, a renowned PVC specialist, once remarked, "PVC Film Sheets transform ideas into tangible solutions."

The production of PVC Film Sheets involves meticulous processes. They are used in packaging, signage, and even medical applications. This material provides a protective barrier while being lightweight. It is easy to handle and mold into different shapes. However, the environmental concerns surrounding PVC are worth noting. Recycling and disposal issues require attention.

Despite its advantages, there can be drawbacks. Quality control during production is essential. Any flaws can significantly affect performance. As industries expand their use of PVC Film Sheets, ongoing research is needed. Striking a balance between functionality and sustainability is key.

PVC Film Sheet is a versatile material made from polyvinyl chloride. This type of film can be clear, colored, or even textured. It has a smooth surface that is easy to clean and maintain. This makes it popular in various applications. People use it in packaging, signage, and protective covers.

One common use of PVC Film Sheet is in laminating documents. It protects papers from wear and tear. Many also use it for crafting, as it can be easily cut and shaped. Additionally, PVC Film is water-resistant. This quality allows for outdoor applications, like banners. However, it is important to consider that while PVC is durable, it may not always be the most eco-friendly choice. Recycling options can be limited, prompting discussions on sustainability.

Despite its popularity, there are drawbacks. Some people find PVC Film difficult to work with. It can be prone to tearing if not handled carefully. Ventilation is needed during certain applications, as fumes can be released when heated. Users should reflect on the balance between utility and potential drawbacks when choosing PVC Film Sheet for their projects.

PVC film sheets are versatile materials with significant properties that make them popular in various applications. These sheets are made from polyvinyl chloride, which grants them durability, flexibility, and resistance to moisture. They typically feature a glossy or matte finish, allowing for aesthetic versatility. PVC film sheets can withstand temperature extremes, offering a continuous service temperature range of -20°C to 60°C. This characteristic is vital in environments where fluctuations in temperature are common.

PVC film sheets are widely used in packaging, signage, and construction sectors. In the packaging industry, their resistance to chemicals and moisture protects products effectively. Industry reports indicate that the global PVC packaging market is expected to reach $20 billion by 2025. This growth reflects the increasing demand for innovative, sustainable packaging solutions. Additionally, PVC film sheets are employed in signage due to their clarity and ability to withstand weather conditions.

Tip: When choosing a PVC film sheet, consider its thickness. A thicker sheet offers better durability but can be less flexible.

The limitations of PVC film sheets should also be considered. Environmental concerns over PVC production may reflect negatively in sustainability analyses. These sheets can release harmful chemicals during production and disposal. Awareness of these issues can guide better choices in material selection.

Tip: Always check the manufacturer's specifications for recycling information.

PVC film sheets are versatile materials widely used across various industries. Their unique properties, such as resistance to moisture and chemicals, make them ideal for specific applications. According to industry reports, the global PVC market is expected to reach $100 billion by 2025. This forecast highlights the increasing demand for PVC products, including film sheets, in countless applications.

In the packaging sector, PVC film sheets are popular due to their clarity and durability. They protect the contents and extend shelf life. Food packaging utilizes these sheets extensively. However, concerns about environmental impact arise. The recycling rates for PVC are lower compared to other plastics. This raises questions about sustainability.

Moreover, in the automotive industry, PVC film sheets are used for interior components. They provide an appealing finish while being cost-effective. Studies indicate that around 35% of automotive plastics are PVC. This reliance underscores the need for industry innovation towards eco-friendly alternatives. Users often grapple with choosing between cost and sustainability. Balancing these aspects poses a challenge for manufacturers.

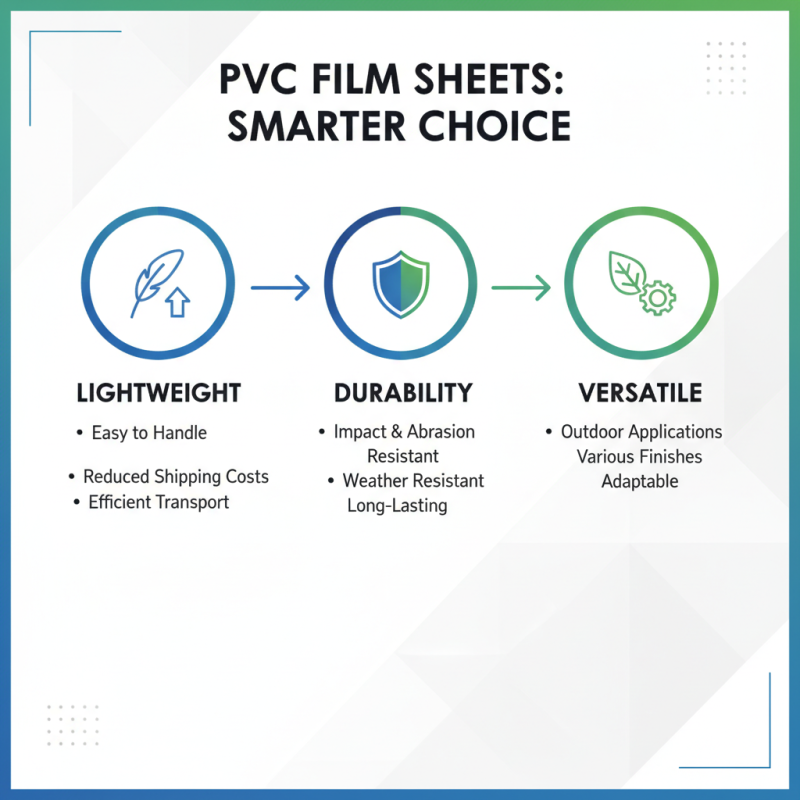

PVC film sheets offer numerous advantages over traditional materials. They are lightweight, making them easy to handle and transport. This can significantly reduce shipping costs. Their durability is another key benefit. PVC sheets resist impact and abrasion. They can endure harsh weather conditions without deteriorating. This longevity is appealing for outdoor applications.

One major advantage of PVC film sheets is their versatility. They can be easily fabricated into various shapes and sizes. This adaptability suits different projects, from signage to protective coverings. Additionally, PVC is waterproof, which is ideal for industries like construction and packaging. It's also easy to clean, saving time and effort in maintenance.

**Tip:** Always check the thickness when selecting PVC film sheets. Thicker sheets provide better durability but may be heavier. Remember, balance ease of use with the project’s needs. Some users find that glossy finishes can be slippery. Consider a matte finish for safer handling.

PVC film sheets are widely used in various industries, but their environmental impact cannot be overlooked. PVC, or polyvinyl chloride, is a plastic that poses significant risks when disposed of improperly. When incinerated, it can release harmful dioxins into the atmosphere. In landfills, PVC takes a long time to decompose, posing sustainability challenges.

The good news is that PVC film sheets can be recycled. Programs to recycle PVC are growing, but they are not yet universal. Many consumers remain unaware of the possibility of recycling PVC. Communities need more awareness campaigns to educate the public about proper disposal. It’s concerning to see so much PVC waste going unrecognized.

Developing efficient recycling methods is crucial. Innovative solutions are being researched, yet implementation remains slow. Industry partnerships can help improve recycling rates. Collectively, we must reflect on our usage of PVC and consider alternatives. Progress is being made, but more steps are necessary to tackle the environmental issues posed by PVC film sheets.

| Property | Description | Usage |

|---|---|---|

| Transparency | PVC film sheets can be produced in transparent forms, allowing for visibility. | Used in packaging, laminating, and display applications. |

| Chemical Resistance | Resistant to various chemicals, oils, and fats. | Ideal for the food and medical industries. |

| Durability | High strength and toughness, making it long-lasting. | Used in construction, automotive, and furniture applications. |

| Flexibility | Can be easily bent and shaped without breaking. | Used for flexible packaging and protective coverings. |

| Recyclability | PVC film sheets can be recycled under proper conditions. | Recycling initiatives aim to reduce environmental impact. |

| Applications in Electronics | PVC film sheets can act as insulation and protective layers. | Used in components like wires and circuit boards. |