Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

In today's industrial landscape, the versatility of PVC film sheets cannot be overlooked. Renowned expert in polymer technology, Dr. Emily Harris, emphasizes, "PVC film sheets are indispensable for various applications due to their unique properties." This statement captures the essence of what makes PVC film sheets particularly valuable across many sectors.

PVC film sheets are used in packaging, construction, and healthcare. They offer flexibility, durability, and resistance to moisture. For instance, in packaging, PVC film sheets protect products while enhancing their visual appeal. However, their extensive use invites questions regarding sustainability and recycling.

As we explore the benefits and applications of PVC film sheets, it's vital to acknowledge the ongoing debate about their environmental impact. While they serve vital roles, industries must reflect on responsible usage. Understanding both the advantages and limitations of PVC film sheets is crucial for future innovations.

PVC film sheets have a versatile range of uses across various industries. These thin, flexible materials are popular due to their durability and practicality. In the packaging industry, they are widely used for their ability to provide excellent barrier properties. They can protect products from moisture, dirt, and other contaminants. For example, food packaging benefits immensely from these sheets, ensuring freshness and safety.

In the automotive sector, PVC film sheets serve multiple purposes. They are used for interior panels and exterior coatings. This enhances both durability and aesthetic appeal. However, companies need to consider the environmental impact of using PVC materials. There are ongoing discussions about sustainable alternatives. This challenge needs careful consideration.

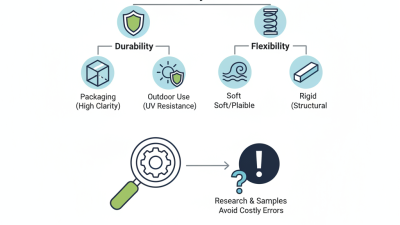

**Tips:** When choosing PVC film sheets, consider thickness and transparency. Too thin may lead to damage easily. Too thick might compromise flexibility. Experiment with samples before bulk orders. It could save resources in the long run. Also, educate your team about proper disposal methods. Awareness can help reduce waste and promote recycling practices in your operations.

PVC film sheets are known for their durability and versatility across various industries. These sheets offer excellent resistance to water, chemicals, and UV exposure, making them ideal for both indoor and outdoor applications. From packaging materials to construction wraps, the uses are endless. Their lightweight nature also makes transport and handling easier, which is a significant benefit in manufacturing settings.

Tips for using PVC film sheets: Always ensure the surface is clean before application. This helps the film adhere better and last longer. Also, consider the thickness of the sheet based on your project’s requirements. Thicker sheets can offer better durability but may be harder to handle. Evaluate your needs carefully.

Another point to reflect on is the disposal of PVC materials. While they are durable, improper disposal can lead to environmental concerns. Explore recycling options to ensure your usage aligns with sustainability goals. Balancing benefits with responsible practices is essential.

PVC film sheets have gained significant traction in both packaging and construction. In packaging, these sheets provide excellent barrier properties. They are resistant to moisture, chemicals, and UV light. A report indicates that the global flexible packaging market is expected to reach USD 300 billion by 2025. This growth highlights the importance of materials like PVC in creating sustainable packaging solutions.

In the construction industry, PVC film sheets are often used in waterproofing membranes and roofing solutions. Their durability and ease of installation make them a favorite among contractors. According to industry research, demand for PVC materials in construction is projected to grow at a CAGR of 4.5% over the next five years. This trend suggests an increasing reliance on PVC for various applications.

Tip: When choosing PVC film sheets, consider the thickness and color that best suits your project. Additionally, it's important to assess their environmental impact, as recycling options may vary. Quality may differ, leading to potential challenges in performance. Always analyze your specific requirements before making a decision.

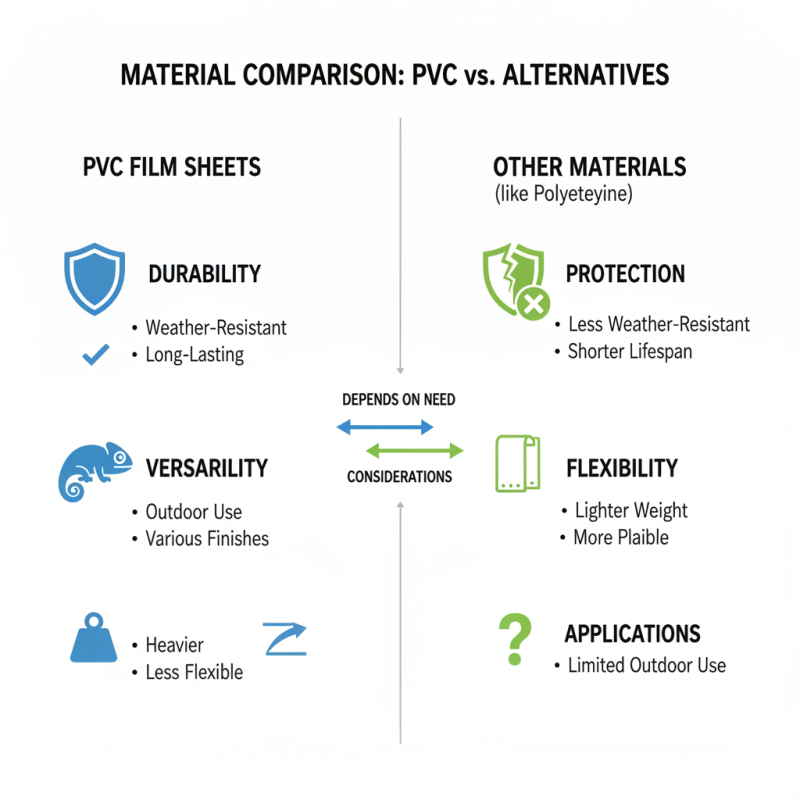

When comparing PVC film sheets to other materials, several factors emerge. PVC is widely recognized for its durability and versatility. It can withstand harsh weather conditions, making it ideal for outdoor applications. Other materials, such as polyethylene, may not provide the same level of protection. But, PVC sheets can be heavier and less flexible than alternatives.

In contrast, materials like polypropylene offer lighter options but might lack the rigidity of PVC. This difference can affect how well they protect contents. For instance, in construction, builders often prefer PVC for its robust qualities. However, this can lead to increased transportation costs due to weight. Understanding these trade-offs is key for various industries to make the right choice.

Moreover, the environmental impact of materials is a growing concern. PVC production can be energy-intensive, raising sustainability questions. While it serves many practical applications, companies must weigh benefits against ecological footprints. This reflection is critical as industries evolve toward greener solutions. Balancing performance and environmental responsibility remains a complex challenge.

PVC film sheets are widely used across various industries. However, their environmental impact raises concerns. PVC production releases toxic substances. These can affect air and water quality. According to a report by the World Wildlife Fund, PVC is among the top contributors to plastic waste. It can take hundreds of years to decompose.

Recycling PVC film sheets is crucial. Studies show that recycled PVC can reduce greenhouse gas emissions by 80% compared to virgin materials. However, recycling rates remain low, with only 9% of plastic materials being recycled globally. This gap highlights the need for better waste management practices.

**Tip:** Consider using PVC film sheets from recycled sources to minimize environmental harm.

Sustainable alternatives exist. Research from the European Commission suggests exploring bio-based materials. These can provide similar benefits with lower ecological footprints. Yet, many businesses may hesitate to switch. The initial investment and uncertainty hinder progress. It is essential to weigh long-term benefits against short-term costs.

**Tip:** Engage in industrial collaborations. Sharing resources can ease the transition to sustainable options.

| Application Industry | Benefits | Environmental Impact | Sustainability Features |

|---|---|---|---|

| Packaging | Lightweight, moisture-resistant, cost-effective | Produces harmful dioxins during production | Recyclable and reusable options available |

| Construction | Durable, weather-resistant, insulative | Long life, but can contribute to microplastic pollution | Can be manufactured using bio-based additives |

| Healthcare | Hygienic, easy to sterilize, flexible | Biodegradable options are limited | Recycling programs for medical-grade PVC in development |

| Automotive | Lightweight, effective sound insulation, customizable | Can release harmful chemicals if burned | Increasingly utilizing recycled materials |

| Agriculture | Protects crops, flexible, UV resistant | Potential soil contamination from PVC waste | Innovative biodegradable films being researched |