Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

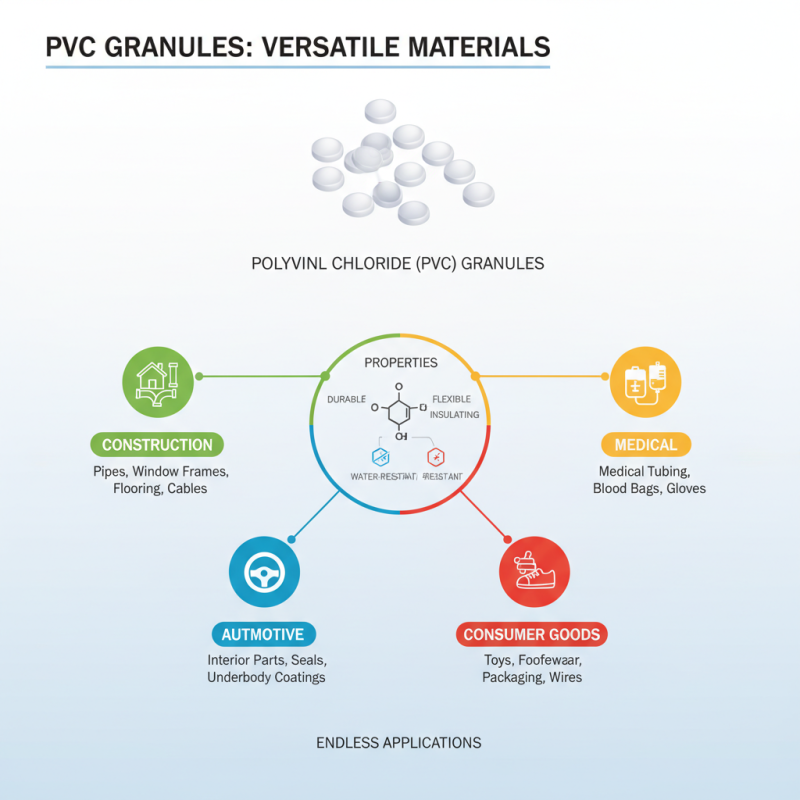

PVC granules are small particles used in various industries. These versatile materials play a crucial role in production. Their applications range from construction to packaging.

In the construction sector, PVC granules contribute to durable materials. They enhance pipes, window frames, and flooring. In packaging, their lightweight nature makes products easy to transport. Many companies rely on PVC granules for efficiency.

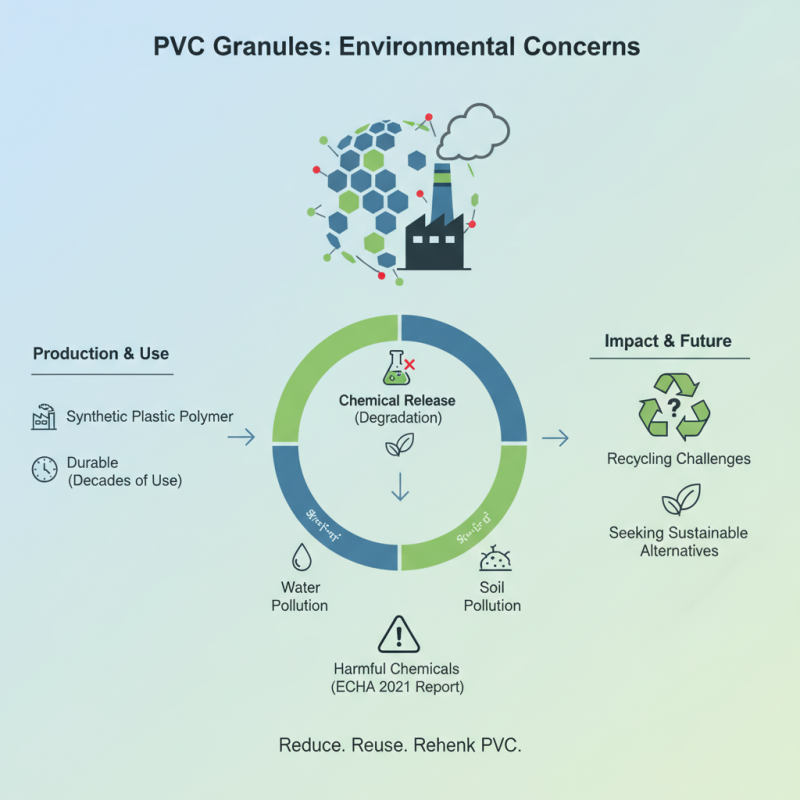

However, the production process is not flawless. Environmental impacts and safety concerns arise from PVC use. Therefore, industries must consider sustainable practices. Finding balance is essential as we continue to utilize PVC granules in practical ways.

PVC granules, or polyvinyl chloride granules, are small beads made from a synthetic resin. This versatile material is fundamental in various industries due to its durability. The global PVC granules market was valued at approximately $70 billion in 2021, and it is projected to grow steadily. Such growth is driven by the increasing demand for sustainable and versatile materials.

These granules are primarily used in construction, automotive, and packaging industries. For instance, in construction, PVC granules are crucial for making pipes and fittings. They offer excellent resistance to chemicals and moisture. In automotive applications, they can be found in interior components, contributing to lightweight and fuel-efficient designs. Research suggests that using PVC can reduce vehicle weight and enhance performance.

However, PVC production faces criticism for its environmental impact. There are concerns about the release of toxic substances during manufacturing and disposal. This brings up debates about sustainability in manufacturing practices. Industries are exploring biodegradable alternatives, yet these options may not match PVC's durability. Balancing these concerns with practical applications remains essential for the industry's future.

PVC granules are an essential raw material in many industries. Their production begins with the polymerization of vinyl chloride monomer (VCM). This process combines VCM with additives, resulting in a versatile polymer. The chemical structure of PVC includes long chains of repeating vinyl chloride units. This structure gives PVC its unique properties.

The manufacturing process can vary significantly. Factors like temperature and pressure influence the final product's quality. After polymerization, PVC is processed into granules. These granules can then be easily transported and stored. However, variations in processing methods can lead to inconsistencies. Some producers may overlook quality controls, resulting in subpar products.

Once produced, PVC granules find use in multiple applications. They are widely utilized in construction for pipes and fittings. Moreover, they serve in the automotive industry for parts and fittings. Despite their benefits, improper disposal of PVC products raises environmental concerns. It prompts industries to reconsider recycling methods. Finding a sustainable approach remains a challenge.

| Industry | Applications | Chemical Composition | Production Process |

|---|---|---|---|

| Construction | Pipes, fittings, siding, and window frames | Polyvinyl Chloride (PVC) | Polymerization of vinyl chloride monomer |

| Automotive | Interior panels, wiring insulation, and dashboards | Polyvinyl Chloride (PVC), stabilizers | Mixing with additives and extrusion |

| Medical | IV bags, medical tubing, and surgical gloves | Polyvinyl Chloride (PVC), plasticizers | Compounding and shaping processes |

| Packaging | Shrink wraps, containers, and films | Polyvinyl Chloride (PVC), additives | Blow molding and casting |

| Electrical | Wire and cable insulation | Polyvinyl Chloride (PVC), flame retardants | Extrusion and cooling |

PVC granules are versatile materials used in various industries. They are made from polyvinyl chloride, a type of synthetic plastic. These granules have unique properties that make them suitable for a multitude of applications.

One of the key advantages of PVC granules is their excellent durability. They resist weathering, chemicals, and corrosion. This makes them ideal for outdoor applications, such as pipes and siding. Another significant property is their lightweight nature. PVC granules are easy to handle, reducing transportation costs. They can also be easily molded into different shapes, allowing flexibility in design.

**Tips:** Always check the quality of PVC granules before purchase. Some might not meet industry standards. It’s essential to conduct a trial to ensure compliance. Additionally, consider the environmental impact, as PVC production can be energy-intensive.

In summary, while PVC granules offer many benefits, it’s crucial to choose the right type for your application. Don’t overlook factors like processing conditions and end-use performance. Understanding these aspects can lead to better decision-making in material selection.

PVC granules play a crucial role in construction and building materials. These granules, made from polyvinyl chloride, are used in various applications. In fact, research indicates that the construction sector accounts for nearly 40% of global PVC consumption. This material's durability and cost-effectiveness make it an appealing choice for builders.

In the realm of building materials, PVC granules are often transformed into pipes, windows, and flooring. PVC pipes are popular due to their resistance to corrosion and low maintenance requirements. According to a report, the global PVC pipes market size is projected to reach $61.4 billion by 2026. However, there are concerns about the environmental impact of PVC production and disposal. Many argue that while it is a useful material, we need better recycling methods.

Windows made from PVC are also widely used. They provide excellent insulation and durability. However, their production process can be energy-intensive. The industry still grapples with how to balance performance and sustainability. There is a demand for more eco-friendly alternatives, yet current solutions often feel inadequate. A certain level of reflection on the industry's practices is necessary to ensure a better future.

PVC granules are widely used in various industries, but their environmental impact is increasingly scrutinized. PVC, or polyvinyl chloride, is a synthetic plastic polymer. It is durable and can last for decades. However, its production and disposal raise serious concerns. According to a 2021 report by the European Chemicals Agency, PVC can release harmful chemicals during degradation. This process can pollute soil and water.

Recycling PVC granules is a growing necessity. Current recycling rates for PVC are relatively low, averaging around 10% globally. The challenges include contamination and the complexity of recycling processes. Yet, advancements are emerging. A recent study highlights new methods that can boost recycling efficiency. These methods can potentially triple the amount of recycled PVC, reducing landfill waste.

There is room for improvement in the circular economy for PVC. Many industries rely on PVC for its properties, such as flexibility and resistance to moisture. However, manufacturers must address how to handle post-consumer products responsibly. Increased awareness and better recycling strategies are essential for minimizing the environmental footprint of PVC granules.