High-Quality Rigid PVC Film for Pharmaceutical Packaging | Trusted Manufacturer & Supplier

As a premier supplier of Rigid PVC Film for Pharmaceutical Packaging, we recognize the distinct demands of the industry. Our films provide exceptional stability and protection for sensitive pharmaceutical products, made from top-quality materials ensuring superior barrier properties. Tailored wholesale options are available for factories and manufacturers aiming to elevate their packaging solutions. With extensive experience at Jiangsu Dahai Plastics Co., Ltd., we prioritize quality and responsiveness in today’s dynamic market. Our knowledgeable team is dedicated to guiding you in selecting the ideal packaging solutions to enhance your offerings. Partner with us to enhance the quality and service of your pharmaceutical packaging.Step-by-Step Guide To Rigid Pvc Film For Pharmaceutical Packaging Dominates Manufacturer

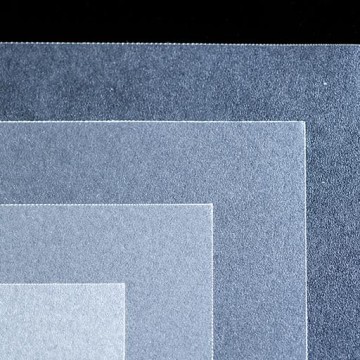

When it comes to pharmaceutical packaging, the choice of materials is crucial for ensuring product safety and efficacy. Rigid PVC film has emerged as a dominant option for manufacturers due to its favorable properties, including excellent barrier performance, clarity, and flexibility in processing. This step-by-step guide will explore the benefits and applications of rigid PVC film in the pharmaceutical sector, making it a top choice for global procurement professionals. The transparent nature of rigid PVC film allows for easy visibility of the product, which is vital in pharmaceuticals where packaging integrity is paramount. Additionally, its superior sealing capabilities ensure that the contents are protected from environmental factors, contributing to longer shelf life and increased consumer confidence. Furthermore, the ability to customize thickness and surface finish makes rigid PVC film versatile enough to cater to various packaging needs, whether for blister packs, shrink wraps, or other forms of containment. Choosing the right manufacturing partner is essential for obtaining high-quality rigid PVC film. Experienced manufacturers utilize advanced production techniques and stringent quality control measures to meet the demanding specifications of the pharmaceutical industry. As global procurement trends shift towards more sustainable and effective packaging solutions, rigid PVC film stands out as a reliable choice that meets both compliance standards and market expectations. By embracing this innovative material, companies can enhance their product offerings while ensuring optimal safety for consumers.

Step-by-Step Guide To Rigid PVC Film For Pharmaceutical Packaging Dominates Manufacturer

| Property | Description | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Thickness | Typically ranges from 0.1mm to 1.0mm | Blister packs, trays, and containers | Good clarity and rigidity | Limited resistance to high temperatures |

| Barrier Properties | Moderate barrier against moisture and gases | Pharmaceutical and food packaging | Cost-effective solution for many applications | Not suitable for long-term storage |

| Transparency | High transparency for product visibility | Display packaging, blisters | Enhances product presentation | Can be prone to scratching |

| Processing | Can be thermoformed, printed, and laminated | Custom packaging solutions | Versatile for various manufacturing methods | Requires special equipment for processing |

| Regulatory Compliance | Meets FDA and other regulatory standards | Medical and pharmaceutical packaging | Ensures safety and quality of products | May incur additional testing costs |

Reasons to Choose Rigid Pvc Film For Pharmaceutical Packaging Leads the Global Market Trusted by Pros

E

Emily Carter

The product exceeded my expectations in terms of quality. Moreover, the after-sale service was top-notch and very supportive.

26 June 2025

I

Isabella Perez

Top-notch quality! The professionalism of their support staff was commendable.

03 July 2025

N

Natalie Ramirez

Great quality and fantastic support from the team! They really know their stuff.

20 June 2025

R

Ryan Green

Quality product! The after-sale support was prompt and effective.

22 May 2025

L

Lucy Thompson

Absolutely love the quality! The after-sale service was reliable and very informative.

11 May 2025

C

Carter Ramirez

Absolutely outstanding quality! Their customer service was highly effective and professional.

14 June 2025